Description

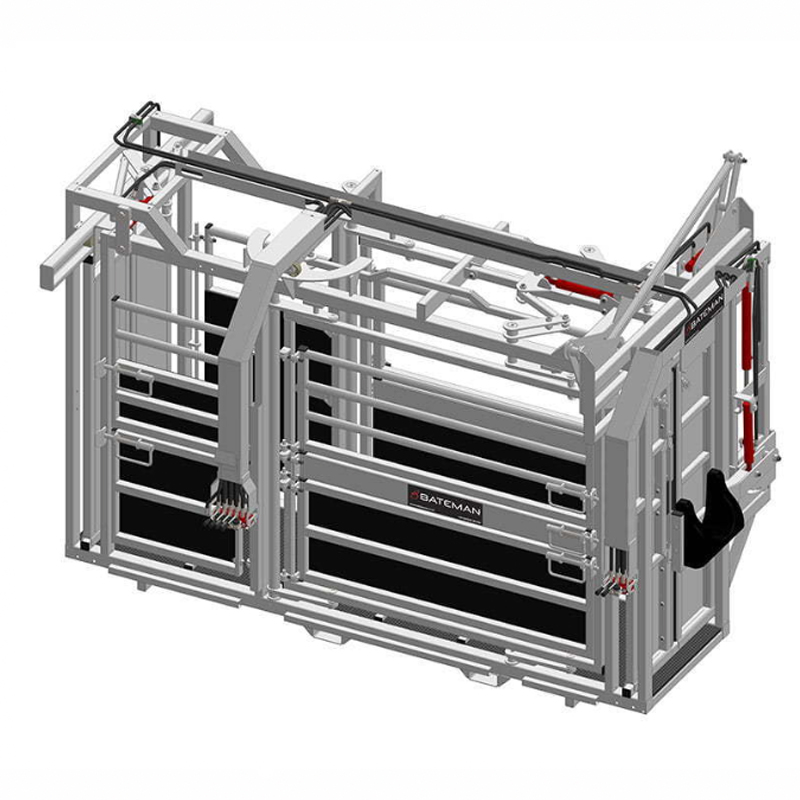

Measuring 3.6 m from gate to gate and tipping the scales at 1,510 kg, this crush is a true heavyweight. Square-section steel uprights form a rigid backbone, clad inside and out with 6 mm polypropylene sheets that deaden clangs and protect hide and horn from bruising. A deep bed of anti-slip bars overlaid with removable rubber matting ensures sure-footed footing, while an integral brisket rail prevents cattle collapsing in the race, which is vital when working tired cows or fractious bulls.

Yet for all that mass, the machine’s hydraulic core moves with remarkable grace. A 240-volt power pack (factory-tuned for whisper-quiet running) drives three key functions:

- Hydraulic squeeze – side walls close smoothly, holding beasts of any width from 850 mm down to 280 mm.

- Hydraulic yoke – a horn-friendly head gate that adjusts from 850 mm right down to 120 mm, perfect for everything from mature bulls to six-month stores.

- Hydraulic chin lift – raises or lowers the head with zero jerks, creating a stable platform for mouthing, bolusing or close inspection.

Touch-sensitive levers give feather-light response, squeeze fractions of a degree or open instantly in an emergency. Noise-damping rotary bolts and nylon ratchet mechanisms keep clatter to an absolute minimum, encouraging animals to load willingly on subsequent passes.

Overall length: 3,600 mm

External width: 1,950 mm

Internal width (hydraulic squeeze range): 850 mm → 280 mm

Internal height: 1,820 mm

Overall height: 2,520 mm

Yoke aperture width: 850 mm → 120 mm

Empty weight: 1,510 kg

These figures translate into real-world versatility. Tall sides comfortably clear the shoulder of pedigree Charolais, while the narrowing squeeze holds slim dairy heifers just as securely. Ground clearance is generous enough for slurry wash-through, and the power pack mounts above splash level, shielding electrics from damp.

Ergonomics

Central to the crush’s appeal is its pivoting control panel. Swing it outward to stand alongside the neck for close veterinary work, or fold it flush against the frame to create a tidy profile in narrow passages. Colour-coded levers (blue for squeeze, green for yoke, red for chin lift) remove confusion when working fast, and soft-return springs hover each valve in the neutral, non-pressurised position, making it safe and energy-efficient.

A second, waist-height mini console sits on the chin-scoop frame, allowing the operator to fine-tune head elevation without taking a single step back to the main bank. Cables and hoses are routed internally, eliminating snag points and delivering a clean, professional finish.

Animal Welfare

- Low-stress entry: the rear hydraulic gate opens fully, creating a wide, inviting lane rather than a tight funnel.

- Quiet operation: nylon rotary bolts and rubber matting mute metallic clangs that can startle nervous stock.

- Natural stance: the brisket rail maintains normal load on forelegs, discouraging animals from dropping to the floor.

- Rapid release: a single lever returns the yoke and squeeze to full width, freeing a panicked beast in seconds.

When combined, those points support faster throughput, improved weight gain (less adrenaline burn), and easier compliance with farm-assurance audit trails.

Built to Outlast the Farm Truck

Bateman has poured decades of crush-building experience into material choice and welding practice. All high-stress junctions use deep-penetration MIG welds, radiused gussets and thicker plate than lesser machines. After fabrication, the entire unit is shot-blasted and hot-dip galvanised, ensuring every corner—including hollow box-sections, is sealed in molten zinc. Even the rubber matting is bolted, not glued, so it can be replaced after years of wear without grinders or welders.

Seamless Integration with Handling Systems

Because dimensions match Bateman’s panel and race modules, the Hydraulic Crush bolts directly into new or existing yards. Fork-lift sleeves mean you can drop it onto a trailer for TB testing on out-farms, then return it to the main shed for routine AI or scanning. If you opt for load bars, a digital indicator bracket is pre-drilled at eye level, putting live weights exactly where you need them.

Cleaning, Service & Power Requirements

Powering the crush is as easy as plugging a 240-volt blue industrial socket into any RCD-protected supply. The hydraulic reservoir features an external sight glass and breather cap, making fluid checks a two-second task. Drain taps under the floor sheet away slurry; side cladding rinses spotless with a low-pressure hose and mild detergent. Bateman recommends a simple annual service—change hydraulic oil, inspect hoses, tighten bolts—to guarantee many years of fault-free operation.

Additional Quiet-Running & Convenience Details

- Rear gate protection strips – The hydraulic sliding gate is lined with rubber buffers that cushion impact as it closes, preventing clatter and protecting hip and tail-bone areas.

- Nylon brush sound dampeners – Discreet brushes are fitted inside key hinge points, absorbing vibration and cutting noise still further when side panels swing shut.

- Fully removable brisket rail – The anti-collapse rail can be lifted out completely for calving cows, heavily bred bulls or specialised veterinary procedures that demand extra floor clearance.

- Plug-and-play load-bar mounts – Factory-welded brackets let you bolt in weighing beams in minutes; no drilling or welding is required, so you can add EID-linked scales whenever budgets allow.

These refinements reinforce the crush’s “safest, quietest, most efficient” promise by trimming decibels, speeding set-up, and giving you flexible access for exceptional cases.

Why Choose the LM Bateman Hydraulic Cattle Crush?

- Operator serenity: pivoting console, touch-control valves, and whisper-quiet pump turn a stressful job into a smooth workflow.

- Beast-proof build: 6 mm poly cladding, hot-dip zinc, and 1.5-tonne mass withstand the roughest bulls.

- Complete access: full-height side doors, TB flaps, chin lift and head restraint open every zone of the animal to treatment.

- Future-ready: optional load bars, plug-and-play power, forklift sleeves—everything considers tomorrow’s demands.

When only the best will do, the LM Bateman Hydraulic Crush sets the benchmark. It is not merely a containment box; it is a precision instrument that streamlines every livestock task, protects valuable carcass quality, and keeps skilled staff safe and productive. Invest once, handle with confidence for decades.

Reviews

There are no reviews yet.