Description

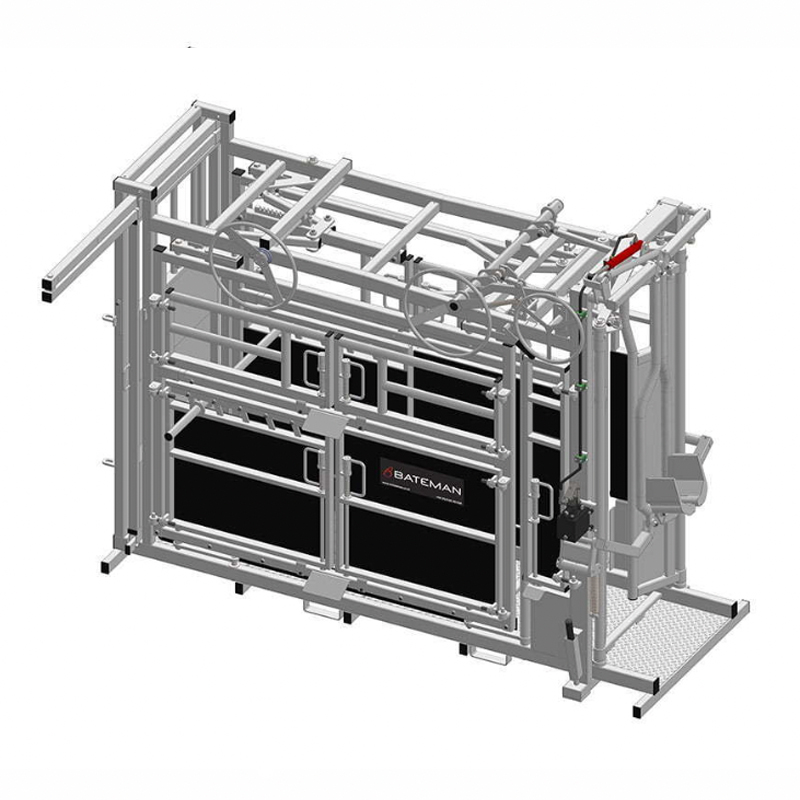

The LM Bateman Tamar Squeeze is built around firm restraint with precise, repeatable adjustment. A semi-automatic head yoke offers manual or automatic operation, the squeeze locks wherever you set it via a rack-and-pinion drive with braked hub, and a hydraulic chin scoop is included from the outset. Quiet running is addressed by rubber flooring and poly cladding, while access is comprehensive through TB doors, full-height side doors and a removable side bar. With forklift brackets integrated and load bars available as an option, the crush arrives ready to install and ready to adapt to changing yard layouts.

Specifications

- Overall length 2,910 mm

- Overall width (crush) 1,110 mm

- Overall height 2,235 mm

- Internal height 1,750 mm

- Internal width 750–300 mm (squeeze range)

- Yoke aperture 100–250 mm

- Width of sliding-door track 1,800 mm

- Weight 880 kg

Control at the head

The Tamar Squeeze centres on a semi-automatic head yoke that can be used in manual or automatic fashion, giving handlers the choice to set and hold the yoke themselves or allow the mechanism to close when the animal presents. Width adjustment across a 100–250 mm aperture range lets you tailor the opening to different head sizes without changing hardware. This flexibility is valuable when moving between smaller cattle and broad-headed types, because the yoke can be set to present a clear, inviting opening and then secure the head without excessive movement.

Secure hold along the body

Side restraint is provided by squeeze-in panels that lock at every point of travel. The locking action is not limited to fixed detents; instead, the sides remain positively held wherever you stop them, which allows a close fit on different animals. The mechanism uses a rack and pinion driven by a hand wheel and backed by a braked hub unit. This arrangement provides steady, incremental control in either direction, resists back-drive, and holds the squeeze where you leave it without drift. Because you can stop the travel exactly where it suits the animal’s width, you maintain alignment for inspection and treatment while keeping movement to a minimum.

Head support as standard

A hydraulic chin scoop is included with the crush. The pump handle is removable, so you can keep the operating area uncluttered when not raising or lowering the scoop. The chin lift can be positioned from either side of the animal’s head, which means you are not tied to a single working side when carrying out tasks at the mouth or jaw. Fine control from the hand pump allows you to bring the scoop up to the precise height required, and to lower it smoothly when finished.

Access designed into every panel

Full-height side doors are spring-loaded for quick opening and closing, giving unimpeded access to the body when needed. TB access doors are built into the side so you can reach the neck area directly without moving the animal within the yoke. A removable side bar offers additional flexibility where more lateral access is required. At the rear, a sheeted sliding door forms the entry gate. The sheeted design improves containment and reduces visual distraction, while the sliding action operates within a dedicated 1,800 mm-wide track, keeping the gate stable through its travel.

Noise management and footing

The inside faces are clad with 6 mm polypropylene, a smooth material that is resilient and helps reduce contact noise. Underfoot, anti-slip bars are combined with a rubber floor. The rubber layer contributes to noise reduction and provides grip, while the bar profile beneath allows liquid to clear. Together, these surfaces are aimed at maintaining sure footing and a quieter working atmosphere around the crush.

Dimensions and working envelope

Overall length is 2,910 mm, with an overall crush width of 1,110 mm and an overall height of 2,235 mm. Internally, height to the roof frame is 1,750 mm. Squeeze travel takes internal width from 750 mm down to 300 mm, enabling a close fit around different body widths. Yoke aperture adjustment spans 100–250 mm. The crush weighs 880 kg, reflecting a robust build. The sliding-door track occupies 1,800 mm across the rear section, giving the door a wide, steady run when opening and closing.

Chassis handling and installation

Forklift brackets are fitted as standard. This simplifies lifting the unit into position and makes it easier to reconfigure handling areas without dismantling the crush. Because the brackets are built into the frame, using pallet tines avoids contact with moving parts or control linkages. The compact overall length allows the Tamar Squeeze to sit within many existing race layouts while still leaving space for an approach pen and exit alley.

Operator interface and latching

Operation is kept straightforward. Twist-and-lift handles are used on key doors and latches so you can release and secure panels with a consistent hand motion. The squeeze hand wheel gives clear, repeatable feedback through the rack-and-pinion gearing, and the braked hub stops the sides from creeping open under pressure. With the chin scoop pump stowed when not in use, the working area around the head yoke remains clear for tools and access.

Through-flow and containment

The sheeted rear sliding door forms a calm entrance, while the semi-automatic yoke creates a consistent point of capture at the front. Once the head is secured, the squeeze sides can be brought in to the required width and held there. When it is time to release, the squeeze can be eased off in controlled increments, and the yoke width can be opened to the next setting. The design balances the need for a restrained posture with a clear path forward when releasing the animal.

Surface materials and cladding

Polypropylene cladding at 6 mm thickness is used on internal faces to provide a durable, non-abrasive surface. This helps limit scuffing and is straightforward to clean. The rubber mat on the floor adds friction for hooves and cushions impact on the steel beneath, while anti-slip bars provide structure and drainage under the mat. Noise-dampening features are present throughout, with the combination of rubber and poly cladding reducing contact sounds compared with bare metal surfaces.

Access doors and side features

TB access doors are positioned along the side, giving a direct line to the neck for testing or treatments that target that area. Full-access side doors open to provide near-complete exposure to the flank and body when needed. The removable side bar can be taken out to create a larger opening, or left in place to maintain barrier protection while reaching inside. Door springs assist with closing to ensure panels return to their secure position without slamming.

The rear entry door runs in a track measuring 1,800 mm across. A track of this width provides a stable guide for the sheeted panel so it can travel smoothly even when opened and closed frequently. A sheeted surface also acts as a visual barrier to the approach area, which can help animals focus on the race ahead rather than activity outside the crush.

Included and optional equipment

The crush is supplied with forklift brackets and a chin scoop included as standard. Load bars are available as an optional extra, allowing you to add weighing capability beneath the crush when required. The core mechanisms (semi-automatic / manual yoke, always-locked squeeze, and hydraulic chin lift with removable pump) are integrated into the standard build.

Applications and suitability

The Tamar Squeeze is described as suitable for all breeds, with adjustment ranges that accommodate different head sizes and body widths. The combination of semi-automatic head yoke, wheel-driven squeeze and standard chin lift provides the set of controls commonly required for routine handling and inspection tasks. With full side access, TB access points and a sheeted rear door, the layout supports a clear approach, secure restraint and consistent release.

Reviews

There are no reviews yet.