Description

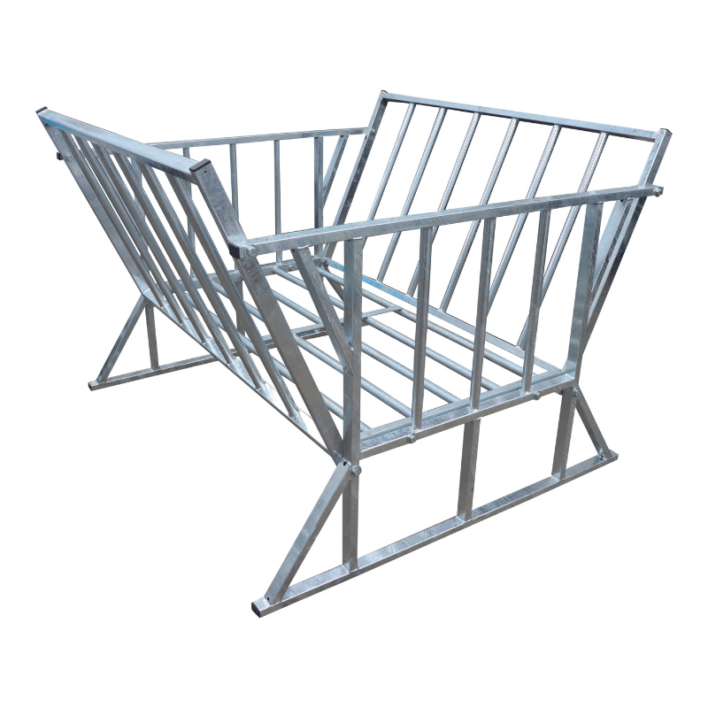

The LM Bateman Heavy-Duty Cattle Ring is the no-nonsense answer for producers who need a feeder that shrugs off rough handling, curbs expensive hay losses, and assembles in minutes. Delivering the twin virtues of strength and practicality, it becomes an everyday ally in the relentless routine of winter feeding. Make one investment now, and reap the rewards of lower wastage, happier cattle, and fewer feeder replacements for years to come.

Diameter: 2,290 mm

Skirt height: 610 mm

Supplied sections: 2

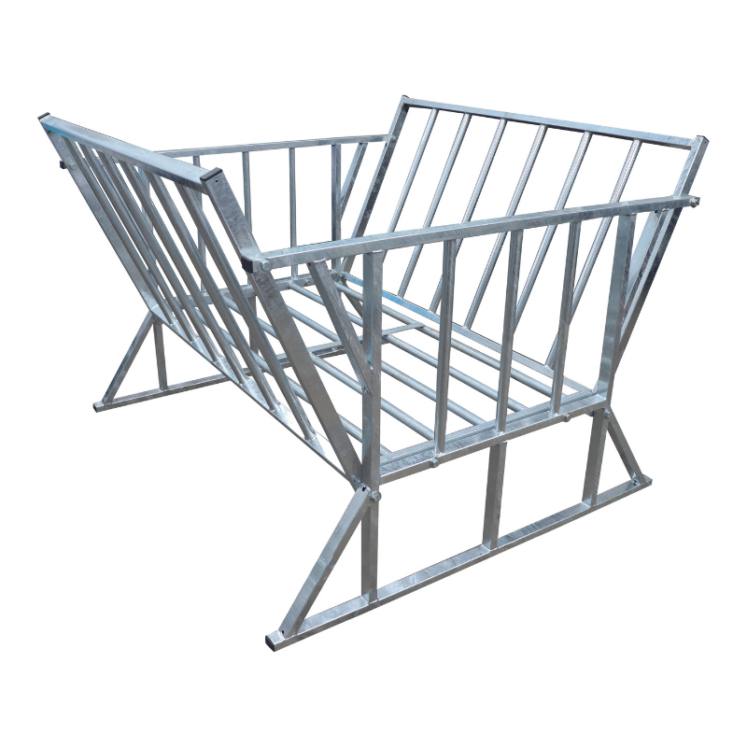

Assembly: Bolt-together with pre-drilled flanges

Finish: Hot-dip galvanised

Purpose-Driven Design

Generous Internal Space

At 2.29 m across, the ring easily accepts a full-size round bale or a dense square-bale stack while still allowing airflow around the forage. The result is drier hay, less mould, and fewer spoilage losses when the weather turns damp.

610 mm Sheeted Skirt

The skirt height has been carefully chosen: tall enough to stop hay from being dragged out and trampled, yet low enough for cows to reach the heart of the bale without strain. Because the skirt is fully sheeted in heavy-gauge steel, wind can’t whistle through gaps and scatter expensive feed across the yard.

Two-Piece, Bolt-Together Construction

Transporting an assembled feeder three metres wide is awkward and costly. To keep freight efficient and on-farm handling simple, LM Bateman supplies this ring as two half-moon sections. Each half is easy to move with a loader or even rolled by hand. When you’re ready to deploy the feeder, align the pre-drilled flanges and nip up the high-tensile bolts, no welding or cutting required.

Heavy-Duty Specification

From the thickness of the sheet metal to the diameter of the tubular uprights, every dimension is uprated over lighter farm-store rings. That extra steel means:

- Greater resistance to denting if a loader accidentally nudges the skirt.

- Improved stability when heavy cattle lean or jockey for position.

- Extended lifespan in corrosive environments such as silage yards or coastal holdings.

Advantages on the Ground

- Maximum Feed Savings: The 610 mm sheeted skirt keeps loose leaves and stems inside the ring, cutting hay losses by up to 10–15 % compared with open-bar feeders.

- Fair Access for Every Animal: A true 360° design and multiple feeding bays let timid or subordinate cattle eat alongside dominant herd-mates, reducing bullying and stress.

- Less Daily Labour: The extra-capacity 2.29 m ring holds one large bale, meaning fewer loader runs and more time for high-value tasks elsewhere on the farm.

- Built-In Long-Term Value: Heavy-gauge, hot-dip-galvanised steel resists rust, while the two-piece bolt-together frame allows easy section replacement instead of full unit swap-outs.

Set-Up and Daily Use

- Delivery & Unpacking

The two sections arrive nested to minimise haulage space. Remove the protective banding, stand each half upright, and position them roughly where the feeder will live. - Assembly

Slide the mating flanges together; insert the supplied coach bolts through the matching holes; tighten with a wrench. A helper keeps the halves aligned while you torque down the nuts. - Loading a Bale

Lift your bale with spikes, angle slightly, and lower it into the ring’s centre. Because there are no overhead bars, loader operators enjoy a clear line of sight, reducing accidental damage. - Site Maintenance

Periodically roll the empty ring to a fresh patch of ground. This limits mud build-up and gives you a chance to scrape away spoiled material. An annual hose-down keeps the galvanised surface free of corrosive silage acids.

Built-In Versatility

Although branded a “cattle” feeder, the Heavy-Duty Ring serves multiple roles:

- Youngstock or store cattle: Cut a bale in half and feed both groups at once.

- Suckler cows outwintering on stubble: Robust enough to drag behind a tractor to fresh ground each week.

- Red-deer or elk enterprises: Horn-friendly spacing prevents antler damage.

- Horse livery yards: Steel skirt stops shod hooves from catching; circular shape discourages dominance fights at a single gateway.

Integration with Other Bateman Feeders

LM Bateman offers a full suite of circular rings (tombstone, sheep-proof, calf creep) and rectangular barrier-mangers. The Heavy-Duty Cattle Ring slots neatly into that line-up, meaning mixed farms can standardise on one trusted manufacturer. Shared spares, familiar bolt patterns, and matching galvanised finish simplify yard logistics and keep the fleet looking professional.

Why Invest in a Heavy-Duty Ring?

Feed-Cost Efficiency

Even modest reductions in hay waste translate into real savings when forage prices climb. Over a harsh winter the ring can pay for itself in conserved feed alone.

Labour Reduction

Increased capacity and rugged build mean fewer bale changes and zero mid-season repairs.

Animal Health

Cleaner feeding zones limit the spread of mud-borne pathogens; better forage presentation supports higher intakes and weight gain.

Long-Term Value

Galvanising, heavier steel, and replaceable halves ensure this ring outlasts cheaper imports—protecting your investment for many winters.

Frequently Asked Questions

Q: Can I tow the ring across pasture?

Yes. Attach a short chain to a sturdy upright and pull gently with a quad or tractor. Keep speeds low to avoid stress on the joint bolts.

Q: Will a 5-foot (1.5 m) wrapped bale fit?

Easily. The 2.29 m internal diameter leaves clearance so netting can be cut away without snagging.

Q: How many cattle can feed at once?

Allowance varies by breed, but expect 12–15 mature cattle to eat comfortably around the ring.

Reviews

There are no reviews yet.