Description

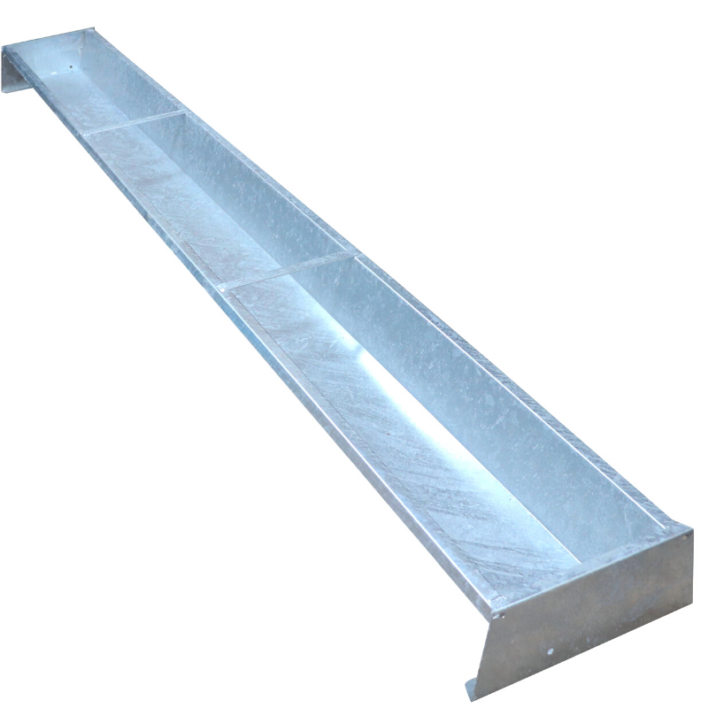

Beef animals, particularly finishing cattle, consume substantial quantities of concentrate and fodder. A shallow, narrow manger quickly overflows, leading to trampling and expensive waste. At 800 mm front-to-back and 700 mm high, the LM Bateman Beef Trough leaves ample space for rolled barley, total-mixed-ration or moist feeds without spilling onto the concrete. The 3000 mm span equates to multiple feeding places in a single run, so cattle can line up comfortably without shouldering each other aside.

- Longer run, fewer joins – a single 3-metre length reduces gaps where feed can collect and spoil.

- Deeper profile – added depth keeps lightweight ingredients (such as chopped straw or mineral balancers) from blowing away in windy passages.

- Raised lip – cattle reach feed easily, yet the upward-turned rim discourages rooting and flicking.

Feed represents the largest variable cost in beef production. A trough that minimises waste, speeds daily routines, and endures for years safeguards that investment. Factor in the avoided expense of replacement hook-over pans, plus the productivity gains from calmer, evenly-fed cattle, and the LM Bateman 3000 mm Beef Trough proves its worth well before its long service life is over.

Cost-Effective Alternative to Hook-Over Barriers

Hook-over troughs certainly have their place, but they are not always the most economical option when kitting out a full shed. The 3000 mm Beef Trough is designed to sit directly in front of a winter-housing feed fence (for example, Bateman’s diagonal or yoke-head gates). Because the trough rests on the yard floor rather than hanging from railings:

- No load stress is placed on the feed fence, prolonging the life of both items.

- Installation is simple—position, check for level, and start feeding.

- One trough covers an entire pen panel in many standard bay widths, cutting hardware costs per linear metre.

Built to Survive the Yard

Daily punishment from 600-kg steers is no small test. LM Bateman engineers all trough feeders to shrug off knocks, aggressive licking, and corrosive feed residues.

- Reinforced end-plates – rigid corners resist distortion if animals push or loaders nudge the trough during bedding-up.

- Robust base runners – keeps the full length off damp concrete, reducing underside corrosion and allowing easy fork-lift relocation.

- One-piece formed body – fewer welds mean fewer weak points where rust can creep in.

- Smooth internal finish – nothing for feed to cling to; a quick scrape or hose-down is all the clean-up required.

Because the 3000 mm Beef Trough is an evolution of Bateman’s proven 2500 mm design—with simply more length and depth—customers inherit the same reputation for longevity that has made the shorter model a fixture in livestock sheds nationwide.

Practical Day-to-Day Benefits

Labour saving

Longer intervals between refills translate to less time hauling barrow loads or running the mixer wagon. Staff can focus on bedding, health checks, and performance monitoring instead of topping up feed every couple of hours.

Feed hygiene

The deeper, smoother channel prevents caked muck from forming at the edges, so intakes stay high and spoilage stays low, an important consideration in intensive finishing barns where respiratory health is paramount.

Animal welfare

When each beast can claim its own space along a 3-metre line, bullying is reduced and shy feeders spend less time waiting. Consistent daily intakes support even growth rates across the group, narrowing weight-range at marketing time.

Shed flexibility

Because the trough is freestanding, it can be:

- Pulled back to widen the scrape passage for tractor-mounted sweepers.

- Shifted outdoors on fine days to serve cattle in loafing yards.

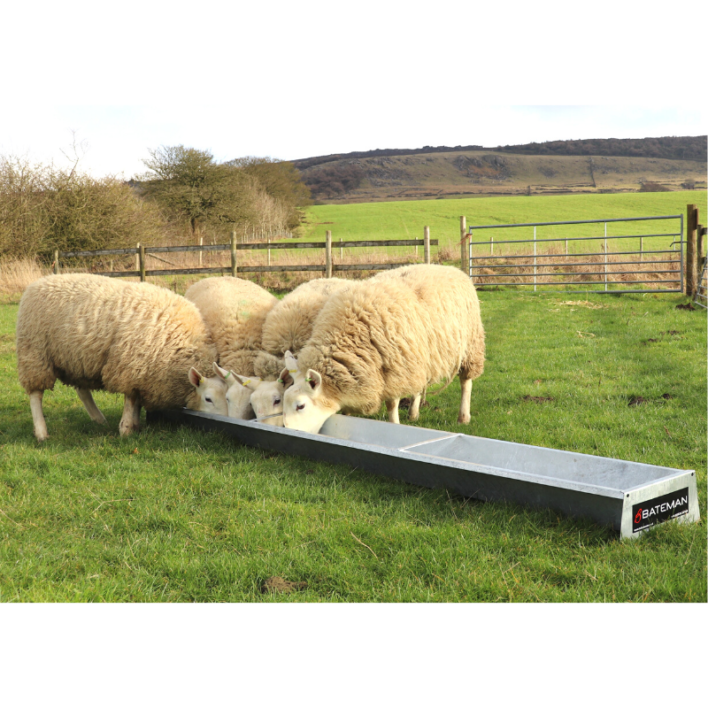

- Used temporarily for other species—e.g., ewes pre-lambing—without dismantling fixed fittings.

6. Integration with Existing Bateman Solutions

Many yards already feature Bateman gates, barriers, or water troughs. The 3000 mm Beef Trough complements these perfectly, both in build quality and in modular sizing. Standard bay widths in portal-frame sheds often measure three metres, meaning a single trough aligns neatly under each panel with no awkward gaps.

Need a shorter run? A 2500 mm version, sharing all the same attributes, is also available from Four Seasons Fencing.

Installation Tips

Level footing: Ensure the concrete apron is even; pack under base runners if needed to stop rocking.

Align with rail: Position the back edge tight to the feed fence so dropped pellets fall back into the trough, not onto the passage.

Allow clearance: Leave a small gap at each end for wash-down water to escape and for easy removal of old feed.

Plan scraper path: If using mechanical scrapers, confirm that the trough sits outside the scraper’s travel line to avoid accidental collisions.

Cleaning and Maintenance

Daily – Brush out fines and cobs left after feeding; this discourages vermin and mould.

Weekly – Rinse with a hose or low-pressure washer. A smooth steel interior sheds residue quickly.

Seasonally – Inspect weld seams and runners; touch up any superficial scratches with a suitable galvanised paint or cold-galv spray to maintain corrosion protection.

Reviews

There are no reviews yet.