Description

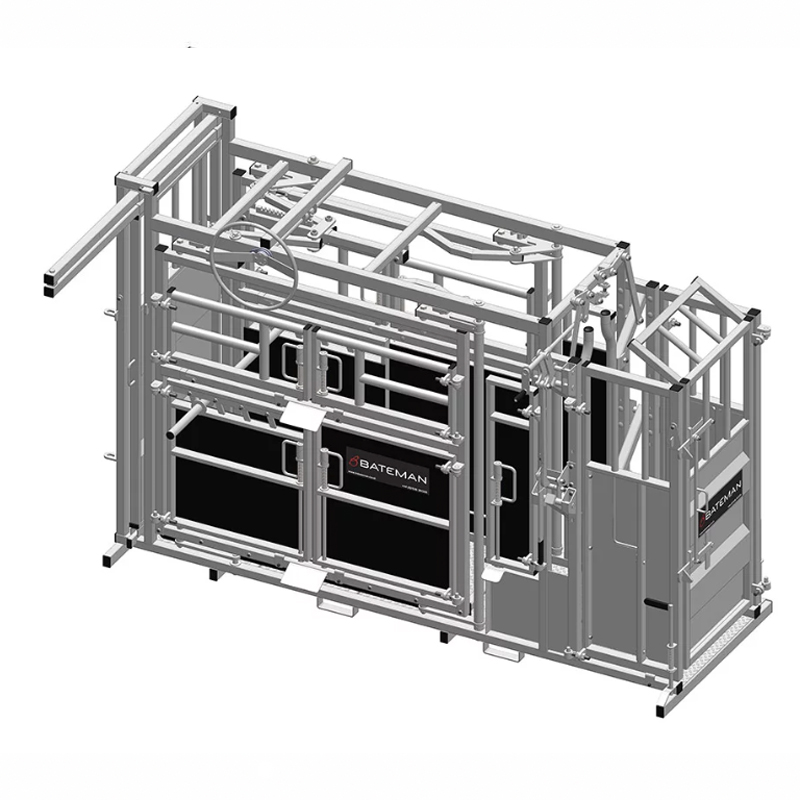

If you need a premium, manually-yoked squeeze crush with strong access and a locking mechanism that holds exactly where you set it, the LM Bateman Ambassador Squeeze delivers those specifics in a compact, heavy-duty build.

Introduced in 2013 and repeatedly cited as LM Bateman’s best-selling crush, the Ambassador Squeeze combines a premium build with a control layout that stockmen recognise immediately. The manual head yoke gives a familiar capture motion, while the squeeze’s distinctive locking behaviour means the sides stay exactly where you put them (no creep and no drift) so the animal remains centred and stable.

The Ambassador Squeeze is described as good for all breeds, including horned cattle, due to the yoke’s full-width opening and adjustable aperture. The always-locked squeeze covers a wide internal width range, ensuring close fit across animals from approximately 50 kg up to large bulls. With durable internal lining, quiet flooring, and comprehensive access, the model focuses on secure restraint, handler protection, and straightforward operation, hallmarks that have kept it at the top of LM Bateman’s sales charts since 2013.

- Overall length: 3000 mm

- Overall width: 1100 mm

- Overall height: 2015 mm

- Internal height: 1780 mm

- Internal width (squeeze range): 750–300 mm

- Yoke aperture: 130–260 mm

- Weight: 812 kg

- Forklift brackets: standard

- Load bars: optional

- Chin scoop: optional

- Foot trim: not available

Overall length is 3000 mm, with an overall width of 1100 mm and an overall height of 2015 mm. Internally, height is 1780 mm. The squeeze narrows the internal width from 750 mm to 300 mm, and the yoke aperture adjusts from 130 mm to 260 mm. The crush weighs 812 kg. Product code is 510-21.

Stated key components include the front safety cage, anti-jump panel, scoop access panel, yoke width adjustment (listed twice in product notes to emphasise its range), cladding with 6 mm polypropylene, squeeze-in sides (wheel-operated and locked in all positions), TB access doors (spring-bolt), full-access side doors, slide-in rump bar with non-return teeth, and a removable side bar. Standard fitments are the forklift brackets; load bars and chin scoop are optional extras.

Manual head yoke with full-width opening

At the front, a manually operated yoke secures the head with adjustment from 130 mm to 260 mm, allowing handlers to set the aperture for different head sizes. When opened, the yoke can clear the full internal width of the crush, providing generous entry and making it suitable for horned animals. This helps present a clear, inviting target as cattle step forward, and once the head is positioned, the yoke closes to the chosen setting for controlled work at the front of the animal. A scoop access panel is incorporated to accommodate the optional chin scoop when extra support is required.

Always-locked squeeze, wheel-operated

Side restraint is delivered by squeeze-in panels that lock at every point along their travel, rather than at fixed notches. The hand wheel-operated mechanism gives smooth, precise movement in and out, and the “always-locked” design keeps the sides positively held wherever you stop; the animal cannot force them open. With an internal width range of 750 mm down to 300 mm, the crush adapts to cattle across a broad weight spectrum—from small animals around 50 kg right up to large, mature stock, while maintaining posture and alignment for the task at hand.

Full access where it’s needed

The crush body is designed to open up quickly and safely around the animal. Full access, spring-loaded side doors provide large working apertures; doors at the top and bottom create reach to the back, flanks, and lower limbs as appropriate, while a removable side bar can be taken out when additional lateral space is required. TB access doors with unique spring-bolt latches are positioned for a clear line to the neck, enabling straightforward TB testing or other neck-based procedures without repositioning the animal.

Rump control and anti-jump protection

At the rear, a slide-in rump bar fitted with non-return teeth prevents backing up once an animal has committed to the crush. Overhead, an anti-jump panel helps deter upward movement at the front, and a front safety cage adds a layer of protection around the yoke area. Together, these elements stabilise the animal’s position and keep the working zone consistent.

Rear sliding door with configurable handing

Loading is managed by a sliding door at the rear. The mechanism can be altered to open from the left or right, allowing the crush to be configured to suit the approach in different yards. Sliding action avoids the swing-arc of a hinged gate, saving space in tight races and keeping operators clear of the animal’s path.

Quiet, secure footing with durable internal surfaces

Contact surfaces inside the crush are clad with 6 mm polypropylene, a tough, smooth material that helps dampen noise and reduce scuffing. Underfoot, anti-slip bars are topped with a rubber floor, combining grip with additional sound deadening. These features make it easier for cattle to find and keep their footing and help to reduce startling noises during operation.

Compact footprint with forklift handling

Despite its comprehensive access and adjustment ranges, the Ambassador Squeeze retains a compact form that fits readily into most handling lines. Forklift brackets are included as standard so the unit can be placed, repositioned, or loaded safely with pallet tines without contacting the operating gear.

Compatibility and options

The crush is chin scoop compatible (available as an optional extra) for those who want to add head support for close mouth work. Load bars can be specified as an optional extra to enable weighing beneath the unit. A foot-trimming kit is not available for this model. The combination of the manual yoke, always-locked squeeze, and rump/security features makes the Ambassador particularly well suited to routine handling tasks that call for clear access and stable restraint.

Working envelope and flow

From entry to release, the Ambassador Squeeze is set up for a controlled, linear workflow. The rear sliding door manages loading into the race; the manual yoke captures and secures the head with size-appropriate aperture settings; the squeeze then closes to a comfortable hold tailored to the animal’s width. With full-front access and side doors opening top and bottom, the handler can reach the required area of the animal quickly. When work is complete, the squeeze can be eased off smoothly and the yoke opened to the next setting, allowing a clear exit without obstruction.

Materials and surface details

Internal polypropylene cladding and the rubber-over-bar floor strike a balance between durability and quieter contact. The cladding thickness is specified at 6 mm, providing a robust lining that is straightforward to clean and maintain. The rubber floor overlay contributes to grip and additional noise reduction, while the underlying anti-slip bars add structure under load and help fluids clear.

Access and safety elements at a glance

The front safety cage and anti-jump panel help maintain animal position in the head area; the rump bar prevents reverse movement; TB doors and full-access side doors deliver reach to the neck and body without releasing the animal; the removable side bar allows wider access when required; and the rear sliding door provides a compact, configurable entrance suited to different race orientations. Each element has a specific role, and together they contribute to consistent, predictable handling.

Reviews

There are no reviews yet.