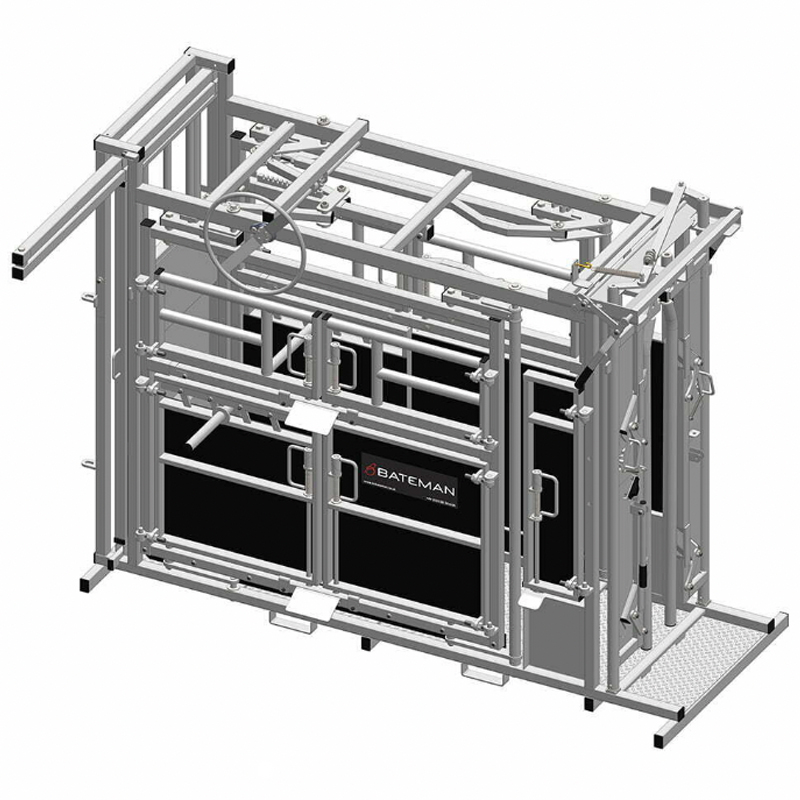

Description

The LM Bateman Devon Squeeze pairs an automatic head yoke (with six width settings and a spring-loaded reset) to an always-locked, wheel-driven squeeze that holds precisely where it is set. With full access side doors, TB doors, a rear sliding door, 6 mm polypropylene internal cladding, and a rubber-over-bar floor, it is specified for controlled capture, clear access and quieter operation. Forklift brackets are standard for straightforward placement, and load bars can be added when weighing is required. The stated adjustment ranges and dimensions support use with small cattle from around 50 kg through to large bulls, within a compact footprint that integrates cleanly into existing handling lines.

- Overall length: 2400 mm

- Overall width: 1100 mm

- Overall height: 2135 mm

- Internal height: 1780 mm

- Internal width (squeeze range): 750–300 mm

- Yoke aperture: 130–260 mm (six width settings)

- Weight: 750 kg

- Forklift brackets: standard

- Load bars: optional

- Chin scoop: optional

- Foot trim: not available

Automatic yoke derived from the Ambassador format

The Devon Squeeze is an adaptation of LM Bateman’s Ambassador Squeeze, specified with an automatic operating head yoke. The yoke presents an open aperture and closes when the animal advances, allowing the operator to maintain position alongside the race rather than at the front. Six width settings are available to match head size across different breeds and ages, with an easy-open yoke release handle to clear the head when you are ready to let the animal move forward. A spring-loaded reset handle returns the yoke to the chosen setting smoothly, so it is prepared for the next animal without manual repositioning of the gates.

Always-locked squeeze with wheel control

Side restraint is delivered by an always-locked squeeze. Using the wheel-operated mechanism, the sides close from an internal width of 750 mm down to 300 mm, and they remain locked at any point along that travel. This means the squeeze does not creep open under pressure; you can stop it at exactly the width required and it holds there. The fine, repeatable adjustment helps keep cattle aligned and still while you work, from approximately 50 kg animals through to the biggest bulls specified for this crush.

Head support and compatibility

The Devon Squeeze is chin-scoop compatible. Pre-drilled fixing points are built in for straightforward installation when the optional chin scoop is specified. With the scoop in place, head elevation and support can be applied when tasks at the mouth or jaw demand a stable platform. (A chin scoop is optional on this model; it is not supplied as standard.)

Access throughout: side, neck, and rear

Handler access is a core part of the design. Full access side doors are spring loaded for easy opening and closing and provide large working apertures on both flanks. TB access doors use spring-bolt catches to give a direct route to the neck area for testing or injection without moving the animal within the yoke. At the rear, a sliding door manages entry and saves space compared with a swinging gate, which is beneficial where the crush is set in a narrow race. A removable side bar can be lifted out to create a wider opening when a particular procedure calls for more lateral space.

Flooring and noise-dampening detail

Underfoot, the Devon Squeeze uses anti-slip bars with a rubber floor laid above. The bar profile provides structure and drainage, while the rubber layer improves grip and helps reduce sound. Internally, 6 mm polypropylene cladding lines the crush to create a smooth, tough surface that is resistant to scuffing and contributes to a quieter environment. These features are specified to promote confident footing and limit sudden metallic contact sounds as animals enter and stand.

Operator controls and reset

The automatic yoke is operated from the side, with a yoke release handle to open the gates and a spring-loaded reset to return them to the selected width. Six width settings are provided on the yoke gate, matching the stated yoke aperture range of 130–260 mm. The squeeze wheel offers clear tactile feedback as you close or open the sides. Control points are positioned for straightforward reach so the operator can maintain a consistent stance throughout routine work.

Dimensions and working envelope

The Devon Squeeze has an overall length of 2400 mm, overall width of 1100 mm, and overall height of 2135 mm. Internally, height is 1780 mm. The squeeze narrows the internal width from 750 mm to 300 mm, and the yoke aperture adjusts across 130–260 mm with six defined settings. Stated weight is 750 kg. These figures reflect a compact footprint relative to the access provided, making the unit suitable for a wide variety of handling layouts where space needs to be used efficiently.

Materials and cladding

Interior surfaces are clad with 6 mm polypropylene. This material selection provides a robust, non-abrasive lining that is straightforward to clean and supports the stated noise-dampening features. The floor’s rubber mat over anti-slip bars adds grip and further reduces sound transmission compared with bare metal.

Rear entry and through-flow

The sliding rear door forms a compact entry with a controlled, linear path into the crush. Once the head is secured in the automatic yoke, the squeeze can be brought in to match the animal’s width and then held at that position. When the procedure is complete, the squeeze is wound back, the yoke release handle opens the head gate, and the animal exits forward, keeping the working area organised and consistent.

Forklift handling and optional weighing

Forklift brackets are supplied as standard, allowing safe lifting and placement with pallet tines without contacting operating linkages. Load bars are available as an optional extra for those who want to integrate weighing beneath the crush. (A foot-trimming package is not available for this model.)

Control of backing and jumping

The Devon Squeeze follows the same approach to controlled positioning seen across LM Bateman’s squeeze range. While specific rump-bar hardware is not listed in the supplied specification for this model, the combination of a secure automatic yoke, the always-locked squeeze, and comprehensive side access provides the elements needed to keep cattle positioned and to complete neck access via the TB doors. The removable side bar remains available when an opening needs to be widened for reach.

Good for all sizes of animal

The specification explicitly states suitability for all sizes of animal. In practice this is expressed through the squeeze range (down to 300 mm internal width), the yoke’s 130–260 mm aperture with six settings, and the overall build that is intended to accommodate cattle from approximately 50 kg to the biggest bulls within the crush’s working dimensions.

Noise-dampening features

The combination of rubber flooring, polypropylene cladding, and spring-assisted closures forms the system’s noise-reduction approach. These features are highlighted in the key features and are intended to reduce the level of metallic impact noise during normal operation.

Reviews

There are no reviews yet.